The durability of custom hang tags inspections are essential to the business whose goal is to provide a high-quality level and leave an impression. Tags should be able to withstand the handling, transportation, and placement in stores without being ripped or destroyed in any manner, affecting the tag’s design.

Durability can be maintained by assessing the materials, printing processes, attaching and finishes. From strings to logos, all these are the ingredients to the lifespan of the custom hang tags. A thorough durability testing process also enables the brands to offer clean, professional packaging, keep clients loyal, and save money on the personalized hang labels. There are eight key points of durability examined in this article.

Material Strength Test

The decision on the base material influences the lifespan of the tag. Clothing custom hang tags are frequently made with cardstock, kraft paper, or coated papers which resist tearing and bending. Measurement of thickness, weight, and finish is done so that the tags do not get damaged within the retail stores, owing to frequent handling. Hardly any metallic materials can also be used to come up with more complex designs or embossing without affecting their structural integrity. Brands are able to achieve this by focusing on the quality of their materials to produce tags that stay put despite time changes in their shape, feel, and appearance.

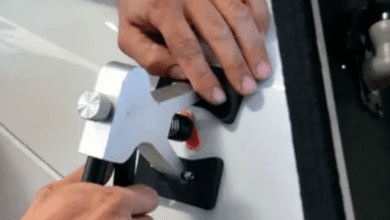

Attachment Method Testing

String custom hang tags have a high rate of wearability depending on the mode of attachment. Tags are to be firmly attached to products with the help of strings or elastic cords, or reinforced loops. The testing presupposes tension and movement to be applied in order to make sure that the tag cannot peel off or fray. Strong attachment schemes on tags enhance customer experience through ensured brand visibility and product information integrity, as the tags are not lost or damaged during the supply chain.

String Quality Examination

Good strings or cords of high quality are crucial for the duration of existence. Elastic hang tags have a flexible hang tag and are securely fastened with a string of elasticity, which should be tested to ensure repeated elasticity. Cotton, jute or polyester strings can be compared in terms of durability, strength and fraying resistance. Trustworthy strings would not have the tags falling off or appearing soiled; the product will be presented professionally without any hassles of customers taking them off.

Print Durability Tests

Elements printed should be clear and vivid. Printed custom hang tags should be tested on abrasion, moisture and fading to make sure that ink or foil finishes do not smear or peel. The testing can be used to establish the most appropriate printing methods to use, such as digital printing, offset printing and foil stamping or foil printing when long-term output is needed. Durable printing preserves brand integrity and makes the product information readable during the product lifecycle.

Logo Longevity Checks

The most significant branding component is a logo. Custom hang tags with logos should be personalized to ensure that the clarity of the tags and their colour remain faithful with the passage of time. Under varied lighting conditions and manipulation, logos need to be tested on adhesion, smudge resistance, and colour consistency. The logo’s durability ensures brand recognition and professionalism, which proves that attention to detail is not only devoted to the product alone but is paid to all visual touchpoints.

Massive Consistency Checking

Massive orders demand homogeneity. Custom hang tags wholesale should have the same quality as all units. Wholesale orders are subject to durability tests on tags sampled on material consistency, string strength, print clarity, and security of attachment. Production variances are identified early in time, whereby all the tags in bulk shipments will have met the expectations of the brands. The step is critical in the effort of retailers to have a unified product display on the shelves or online.

Wear and Tear Simulation

Real-world handling simulation makes the tags resistant to use. Wholesale custom hang tags are supposed to be tested in bending, folding, rubbing and exposure to the environment, like humidity or light. The tags which withstand the simulated wear remain professional even when they are handled by the staff or customers numerous times. This type of test is used to determine the weak areas in the brands, to select the right materials, and to strengthen the method of attaching materials to maximize the longevity.

Supplier Collaboration Insights

Cooperation with manufacturers makes tags durable. Technical skills may be needed in cutting, printing and attaching strings in the custom hang tags of clothing. Working with older suppliers would ensure quality assurance, design precision, and fulfill durability criteria. Brands can obtain tips or recommendations on the choice of materials, print finishes, and testing procedures and thus obtain consistent and high-quality tags in reference to professionalism and detailing.

Conclusion

Custom hang tags durability tests are necessary to create durable professional hang tags that can improve product display and brand identity. As long as the material is strong, the strings are good, and the ways of attaching are good, the longevity of the print, the logo combinations, the bulk uniformity, wear tests, and cooperation with the supplier, all of this leads to the credible and visually pleasing hang tags.

Durability testing will help ensure that the custom hang tags are structurally sound and wearable, as well as make an impression on the customers. Brands take a risk to invest in quality and test their products. By doing so, they assure their brands, enhance their image and provide a professional experience that increases their retail presence and consumer trust.