Plastic compostables are gaining popularity in businesses interested in using such materials to serve their beverages in highly practical ways. These products are as durable as conventional plastics and promote responsible disposal. The choice of material is very important as it provides the cup with the structural integrity of the usage, as well as allows the cup to be completely decomposed in composting conditions. Manufacturers present alternatives, such as plant-based fibers and biodegradable coatings, and all these are aimed at satisfying food safety requirements.

Special designs can also be done with the custom compostable products, and this can be done to improve customer experience. Insulation material can be designed to keep drinks warm, give more hearty items some support, and accommodate diverse lids without affecting the compostability. These features enable them to be used in operations with high volumes with minimal waste and also ensure the quality of the products.

Innovative Design Options

Flexibility in design differentiates custom compostable products, as compared to traditional products. Businesses can be made to be unique in shapes and sizes to fit various types of beverages. This flexibility enables brands to align the visual identity of their packages with general marketing practices to give a complete representation on the cup to the lid.

One of the applications is printed compostable cold cups. The printing process does not compromise the compostable properties of the material since it helps in the development of high-quality graphics. Logos, patterns, or promotional content can be implemented by the brands, which is effective as it influences the visual impact. With such designs, the standards of presentation are advanced, and at the same time, the disposal requirements of the environment are met.

Cost Efficiency Strategies

Tailored compostable products can have a long-term economic benefit to companies. Initial investment might be more than the standard plastic cups, but their toughness will minimize the product failures and will minimize the replacement demands. The sourcing options, like the custom compostable cold cups wholesale, will save large operations a lot of money. Bulk buying also means that the companies do not have to worry about the constant supply of products, but can store them in stock without the need of shipping them every time.

Also, businesses will be able to achieve inventory optimization by choosing compostable cold cups bulk packs based on the volume requirements. This will reduce storage and wastage. Businesses can merge the mass purchasing with customized lid and cup designs to optimize workflow with a low volume of labor and operation in the long run.

Functionality Enhancements

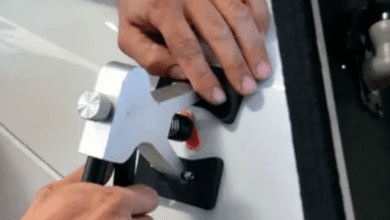

One of the considerations that must be made on custom compostable products is practical performance. Cups should not break under the pressure of condensation, temperature changes, or repeated use without breaking Integrated solutions: Custom compostable cold cups with lids are offered so that spills can be avoided, and the structure should be stable when transferred. Lids are supposed to be fitted well, with a variety of drinks, including iced coffee and smoothies.

It is also possible to choose variations that facilitate stacking and storage by businesses. Well-designed also avoids deformation in handling, and this is very important in high-throughput operations. The material strength and new lid patterns make sure that the product is functional, and at the same time, the product achieves sustainability objectives.

Brand Differentiation

Packaging is a strong branding instrument. Compostable cups with brands enable companies to convey their values of responsible sourcing as well as strengthen their visual language. The positioning of logos, color,r and printed messages can give a customer a higher perception and loyalty can be developed. Every cup is turned into a marketing tool that determines consistency between the operational functionality and brand storytelling.

Visualization is not the only form of customization. Firms have an opportunity to experiment with tactile finishes, cup shape, pe, pes, and lid design, one that improves user experience. This distinction plan will place the businesses as proactive and responsive to consumer expectation adhering to the standards of compostable materials.

Supply Chain Take into Account.

The collaboration with the trusted suppliers essential for the consistency of operations. Biodegradable cups wholesale are standard in quality and supply. Suppliers are advantageous to the businesses because they allow them the opportunity to make custom orders, provide timely delivery and quality assurance during manufacturing and shipping.

The supply chain planning also involves checking the compliance with the composting standards and food safety regulations. Choosing a supplier whose records are clear will help in the supply of products that are performanenvironmentally-compliant liant under the required standards. There is a smooth coordination among suppliers and businesses, which eliminates the risk of stock shortages, production delays or compliance difficulties.

Market Integration

Studies on the food and beverage industry are increasingly being embraced in the use of custom compostable products. The solutions can be adopted by establishments such as cafes to large-scale catering services without interfering with the working processes. Interoperability with existing service systems is not a problem, since products have a size and format that can fit into the standard equipment.

Sustainable packaging affects consumer buying behaviors. The opportunity to integrate custom wax paper for food solutions into the business will provide businesses with a competitive edge in the market, as they will be able to adjust their product offering to the increasing popularity of responsible materials. Such alignment in the long run is capable of raising customer retention, reputation, and overall efficiency in the operation.

Conclusion

Made of Custom compostable material, these custom products are designed to be practical, designed to be flexible and modular, and responsible in the use of material, making them ideal in the current operations of beverage service. Using printed designs or wholesale sourcing and lid integration, businesses will be able to improve their performance and customer experience. ConA considerable choice of materials and suppliers guarantees efficiency in the operation, influence of brands, and eco-friendly waste disposal, which makes these solutions indispensable in modern service settings.